3D printing is a new technology that is rapidly gaining popularity and becoming affordable. A few years ago, 3D printers were expensive. While advanced printers can still be costly, many consumers can afford consumer-oriented printers. Nowadays, these printers can be used to create a wide variety of useful, artistic, or fun items. One of the best innovations in 3D printing technology is rapid prototyping. Many CNC machining services use this technology to produce their clients’ products massively. As we know, the most significant advantage of a home 3D printer is its versatility. It can print jewelry, ornaments, and tools, as well as mugs, vases, cookie cutters, napkin rings, and other items. Now, let’s look at how this technology works and the two best innovations in 3D printing technology.

How 3D Printers Work

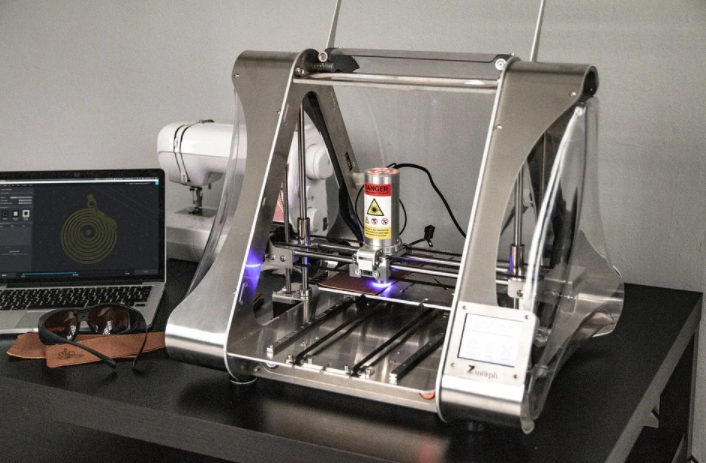

The first step in creating a 3D printed object is to design it. This can be done with a 3D art, CAD (computer-aided design), or animation program. The STL file is created from the computer model. The STL file is then read by a second program, cutting software. It is converted to G-code. This code tells the printer how to print the object in horizontal layers. The printer then prints these layers one by one, starting with the lowest layer. Most consumer 3D printers use plastic extrusion printers (or FDM printers). There are also high-quality FDM printers, but these are more likely to be purchased by consumers.

The printers make objects by melting plastic filament and extruding it onto a platform. Once the plastic is extruded from the printer’s extrusion nozzle onto the platform, it solidifies almost immediately. As the object gets more profound, the medium and nozzle move in different directions. Each extruded plastic layer merges with the one below. This is often called additive manufacturing.

Rapid Prototyping as the Most Advanced 3D Printing Technology

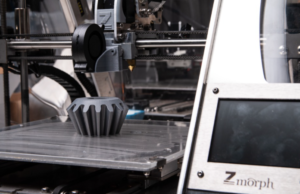

Product designers face many challenges. One of the biggest challenges for product designers is not representing what the final product will look like. There are still many areas that can be improved in 3D CAD. Rapid prototyping, also known as additive manufacturing, is becoming increasingly popular among engineers, designers, and manufacturers.

Product designers face many challenges. One of the biggest challenges for product designers is not representing what the final product will look like. There are still many areas that can be improved in 3D CAD. Rapid prototyping, also known as additive manufacturing, is becoming increasingly popular among engineers, designers, and manufacturers.

It allows manufacturers to understand the potential of products better. RP makes things much more manageable. Rapid prototyping offers many benefits to industrialists and product designers. Designers can test prototypes before they are created. This 3D printing technology also saves time and costs because it requires less material to manufacture products. People love 3D printing technology because it allows them to minimize design issues. There are many quality issues in printing. However, with this technology, defects can be detected before mass production begins.

3D Pen as the Most Affordable 3D Printing Technology

Some people consider the cost of a 3D printer to be too high. 3D pens, which are relatively inexpensive, could allow more people to create 3D objects and have fun doing them. Several different companies manufacture 3D pens. Most pens work by plugging the device into a power outlet or USB port and then inserting plastic filament into the hole at the end. The pen heats the filament, and the “spring” extrudes the soft material. The plastic then solidifies.

The pens can be used to draw on a flat surface or in the air with extruded material. You can create real 3D objects as well as one-dimensional objects on a raised surface. Some manufacturers offer free models for download. The model can be traced with a pencil. You can then move the model to a higher position. To create complex objects, you can join several paths with the pencil.